Our Services

Manufacturing & Supply of various Industrial Equipment & Systems tailor-made to meet specific requirements

Service

We offer a wide range of advanced equipment and systems designed to meet the demanding needs of processing industries.

Chemical Processing Equipment

- Reactors (Jacketed / Limpet Coil)

- Heat Exchangers (Shell & Tube / Plate)

- Distillation Columns

- Crystallizers

- Nutsche Filters / Filter Dryers

- Agitated Vessels

- Storage Tanks (MS/SS)

- Scrubbers (Wet / Dry)

- Centrifuges

- Evaporators (Falling Film / Forced Circulation)

Conveying & Material Handling

- Screw Conveyors & Feeders

- Pneumatic Conveying Systems

- Vacuum Transfer Systems

- Bucket Elevators & Belt Conveyors

- Rotary Valves & Airlocks

Mixing & Blending

- Ribbon Blenders

- Paddle Mixers

- Conical Screw Mixers

- High-Shear Mixers

- Double Cone Blenders

Magnetic & Metal Separation

- Inline Magnetic Separators

- Rotary Magnets

- Metal Detectors

Weighing, Batching &; Automation

- Load Cell-Based Weighing Systems

- Recipe-Based Batching Units

- PLC Panels & SCADA Integration

- Smart HMI Interfaces

Roasting & Thermal Processing

- Spice/Nut/Seed Roasters

- Tray, Rotary, and Flash Dryers

Dust & Pollution Control

- Baghouse Filters

- Cyclone Separators

- Wet & Packed Bed Scrubbers

- Explosion Protection Systems (Vents, Suppression, Isolation)

Storage & Discharge Solutions

- Silos, Hoppers & Bins

- Butterfly, Knife Gate, and Slide Gate Valves

- Vibrating Bin Dischargers

- Flow Aids & Air Pads

Size Reduction & Classification

- Jet Mills & Micronizers

- Pin Mills & Hammer Mills

- Classifying Mills

- Lump Breakers & Crushers

Material Handling Equipment

All types of Screw Conveyors

- Efficient Material Movement: Screw conveyors are capable of moving a wide variety of materials, including powders, granules, and small-sized materials.

- Customizable: These conveyors can be tailored to fit specific needs, including adjustments to length, diameter, and material of construction (stainless steel, carbon steel, etc.).

- Compact Design: They occupy less space compared to other bulk material handling systems, making them ideal for tight spaces.

- Dust-Free Operation: Screw conveyors operate in an enclosed system, minimizing dust and preventing contamination, which is especially important in industries like food and pharmaceuticals.

- Versatile Applications: Commonly used in industries like food processing, chemicals, cement, sugar, and wastewater treatment.

Material Handling Equipment

Bucket Elevator

- Vertical Lifting: Ideal for moving bulk materials to great heights efficiently, saving both time and labor.

- High Capacity: Capable of handling large quantities of material at a fast pace, making them suitable for high-production environments.

- Durability: Built to withstand harsh environments and heavy-duty applications, with components made of durable materials such as stainless steel, carbon steel, or plastic.

- Space Efficient: Since bucket elevators operate vertically, they require less floor space compared to other material handling systems like conveyors.

Material Handling Equipment

Belt Conveyors

A belt conveyor is a widely used mechanical system designed to transport materials from one location to another, typically in a straight line or at an incline. It consists of two or more pulleys with a continuous loop of material—the conveyor belt—that moves materials efficiently across various distances. Belt conveyors are commonly used in industries such as mining, food processing, manufacturing, and logistics for handling bulk materials or packages.

Material Handling Equipment

Rotary Airlock Valve

A rotary airlock valve is a critical component used to regulate the flow of materials between two areas with different pressure levels, ensuring an airtight seal. It is designed to allow continuous material discharge while preventing air or gas leakage, which makes it highly effective in applications involving dust collection, pneumatic conveying, and material feeding.

Material Handling Equipment

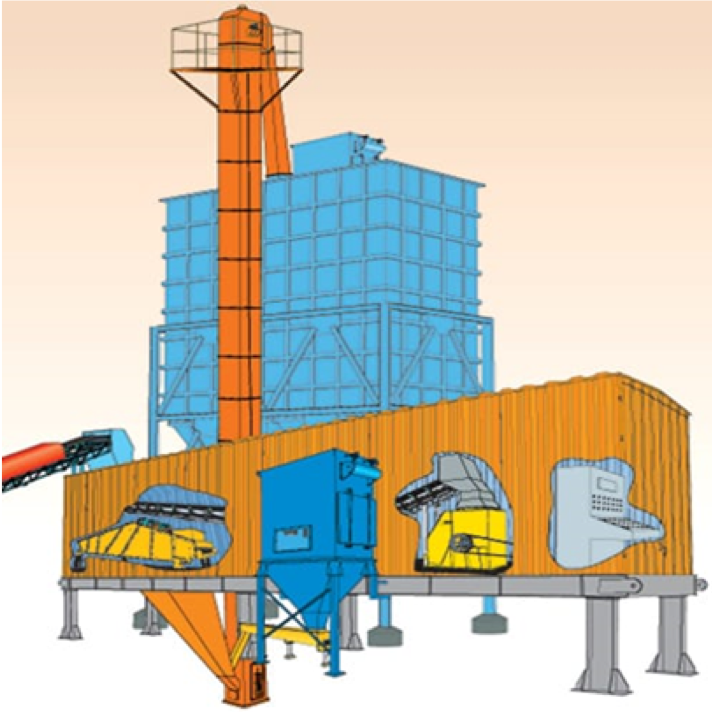

Coal Handling Plants

A coal handling plant (CHP) is an essential part of a thermal power plant, designed to handle, process, and transport coal used for energy production. It plays a critical role in ensuring that coal is delivered efficiently to the boiler for combustion, which is necessary for generating electricity. The plant incorporates various equipment and systems to manage coal from the point of arrival to storage, crushing, and feeding into the furnace.

Pricing Plan